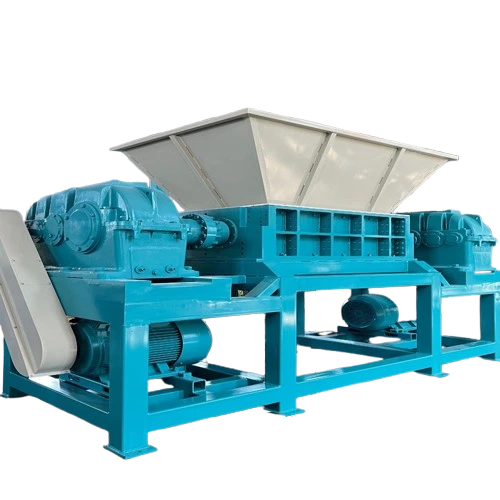

Double Shaft Shredder For Scrap Recycling - HUATAO Machine

The 1500-type double-shaft shredder produced by our company can shred large pieces of materials that are difficult to shred, basket materials, pipes, plates, wood, tires, scrap metal barrels, and large rolls of film.

Product Introduction

The 1500-type double-shaft shredder produced by our company can shred large pieces of materials that are difficult to shred, basket materials, pipes, plates, wood, tires, scrap metal barrels, and large rolls of film; the combined structural frame is precisely processed with extra-thick plates, the powerful rotating shaft of large-angle hexagonal columns, and the large-diameter solid input hopper can be safely put into large raw materials. The double-shaft shredder series sold by our company can be customized according to the specific usage of the customer. Welcome to contact us for consultation.

Product Parameters

|

Model no |

HTDS 1500 |

|

Knife box size |

1500x1100mm |

|

Equipment size |

4*1.7*2.4m |

|

Spindle speed |

30-40r/min |

|

Motor Power |

45KW |

|

Reducer |

2 sets |

|

Blades material |

55crsi, 99crsi, Cr12mov, Skd-11, H13, Dc53 Or As Your Demands |

|

Bearing |

China brand |

|

Power unit |

1 sets |

|

Logo & color |

Customized |

Application Area

The double-shaft shredder model 1500 is mainly suitable for shredding truck tires, mattresses, large waste furniture, waste home appliances, scrap steel, scrap iron, urban garbage, domestic garbage, electronic waste, scrapped vehicles, etc. The main function is to shred large pieces of materials that are inconvenient to transport into materials that meet the requirements through the shearing of the shredder.

The machine is mainly composed of a shredding blade group bearing box, a box bracket, a feeding system, a power system, and an electrical control system. It is a garbage recycling station, RDF production, car recycling line, etc recycling line's first choice.

Features

Product advantages of shredder:

1. The knife seat and blade on the rotor are detachable, which is convenient for cleaning, maintenance and care:

2. Each moving knife has 4 cutting edges, which can be rotated 90° for continued use after wear;

3. The main shaft is driven by a gear reducer, which runs smoothly, has low noise and high torque;

4. The PLC program control system is adopted, which can automatically reverse forward and reverse, making the machine run stably;

5. The box body is welded and tempered after welding;

6. The moving knife is installed in a position so that the gap between the moving knife and the fixed knife is the same:

7. The moving knife seat is connected to the knife shaft with screws in an embedded manner, which can avoid the knife falling phenomenon caused by long-term vibration of the welding type.

8. It is convenient to transport after shredding, with low transportation cost, increased transportation efficiency and convenient secondary processing.

Application

Just leave your email or phone number in the contact form.

viber/Skype: +86 13383116640

E-mail: Marketing@huataogroup.com