Lightweight Fully Automatic Plastic Recycling Machine Fully Automatic Plastic Recycling Machine Company

Product details of the fully automatic plastic recycling machine

Quick Overview

The whole production of HUATAO Machine fully automatic plastic recycling machine is supported by the technicians with extensive industry expertise and the leading production technology. This product is ensured with optimum quality and durability. This product perfectly meets the actual requirements of customers and has great market potential.

Product Introduction

With a focus on quality, HUATAO Machine pays great attention to the details of fully automatic plastic recycling machine.

Product Introduction

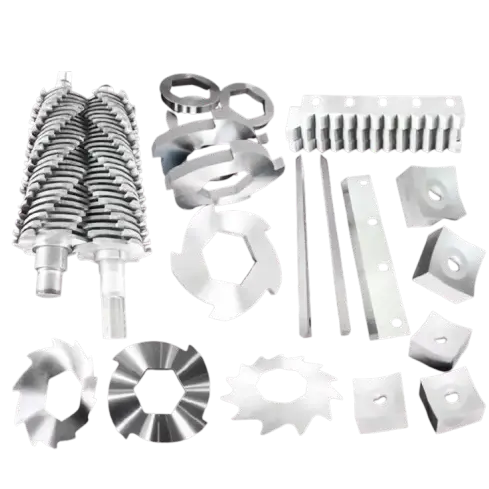

1. The double/four-shaft shredder blades work mainly through the relative rotation of the double/four shafts. When the material enters the shredder, the blades on the two shafts rotate in opposite directions, using the blades to cut, shred and squeeze the material.

2. For materials of different hardness, the blades work slightly differently. For example, for soft materials, such as plastic film, the blades mainly break them by cutting and shredding; for hard materials, such as metal scraps, the blades need to use strong shearing and squeezing forces to break them.

Product Parameters

|

Material |

9crsi, skd-11, 55sicr, h13, skh, dc53, ld, cr12mov and etc |

|

Hardness |

55-64 Hrc according to customers' requests |

|

Application |

Plastic recycling, metal recycling, wood recycling, e-waste recycling, rubber recycling, textile recycling, and etc |

|

Dimension |

Customized size |

Features

Material:

1.High hardness: In order to effectively shred various materials, the cutter usually uses high-hardness materials, such as alloy steel, die steel, etc. Its hardness range is generally between HRC55-64, which allows it to withstand greater pressure and friction, and maintain good performance when shredding harder materials such as metal and wood.

2.Good toughness: In addition to hardness, the cutter also needs to have good toughness to prevent breakage during the shredding process. Especially when dealing with materials containing impurities or unevenness, a cutter with good toughness can better cope with impact force. For example, some cutter materials with alloy elements such as molybdenum (Mo) and vanadium (V) can effectively improve toughness.

3.Diverse blade shapes: The blade shapes include straight blades, spiral blades, etc. The processing accuracy of straight blade cutters is relatively easy to control, and it is suitable for processing materials with high dimensional accuracy requirements; spiral blade cutters can gradually roll in and shred the material during rotation, and are more suitable for processing long-fiber or tough materials, such as waste conveyor belts, fiber fabrics, etc.

4.Staggered blade layout: The blades of the double-shaft shredder are staggered on the shaft. This design allows the material to be shredded from multiple angles after entering the machine, enhancing the shredding effect. For example, when processing blocky wood or plastic, the staggered blades can form a cross shear force, which allows the material to be shredded into small pieces faster.

Application

Company Advantages

SHIJIAZHUANG HUATAO IMPORT AND EXPORT TRADE CO.,LTD. (HUATAO Machine) is a modern enterprise that insists on independent research and development, production and sales of E waste recycling line,medical waste recycling line,RDF/SRF line,Texitle recycling line,Waste Recycling Machine, Shredder Machine,Crusher Machine Waste Recycling Machine Spare Parts. The mature and reliable after-sales service guarantee system is established to guarantee the quality of after-sales service. This helps improve customers' satisfaction for HUATAO Machine. Our products are of high quality and great safety. Besides, they are packed tightly and shockproof. Customers can rest assured to purchase our products and are warmly welcomed to contact us for details.

viber/Skype: +86 13383116640

E-mail: Marketing@huataogroup.com